Do you know that Petrol stations (or Gas Stations) create ample toxic emissions that we don’t even notice?

Everyone had paid a visit to their nearest petrol stations for refueling.

While approaching the petrol station we feel a whiff of petrol & petroleum products.

Are you aware that this smell is caused by volatile hazardous components vaporized during the refueling process?

Liquid petrol evaporates inside the vehicle’s fuel tank and fills the empty space.

During refueling, incoming fuel pushes the petrol vapors out of the tank and unless controlled, they escape into the atmosphere as toxic emissions.

This is the pertinent source of the visible mist and strong odor that we feel at the petrol pumps while refueling.

In this article, we will discuss –

- Petrol station environmental impacts

- Various types of fuel contaminants at petrol stations & their effects.

- Methods to reduce toxic emissions by installing a vapour recovery system at fuel station.

- Vapour recovery system in India

[lwptoc titleFontSize=”130%” itemsFontSize=”120%” backgroundColor=”#ffffff” borderColor=”#61d60e”]

Cause of Toxic Emissions at Petrol Stations

Who did not want to breathe in the fresh air?

In the Indian context, our market scenario is changing rapidly owing to which clean air now becoming scarce day by day.

Out of the several cited reasons one of the biggest contributors to pollution & toxic emissions is petroleum and petroleum products.

Smell-causing major volatile organic compounds (VOC) are benzene, toluene, and xylene present in petrol (major quantity) and petroleum products.

During refueling or tanker unloading into the underground storage tanks, these volatile fuel contaminants will evaporate in the atmosphere causing pollution.

As the name suggests, these compounds are volatile and react readily with other compounds in air (i.e. Oxides of Nitrogen) under the presence of sunlight to produce white haze pollution.

Apart from polluting the air, these petroleum products are also responsible for land pollution due to leak and spillage occurred during the refueling process.

Fugitive losses or toxic emissions from retail petrol stations can be classified into the following categories.

1. Toxic emissions during Tanker Unloading/Loading Operations

The loading and unloading of petroleum is a complex and potentially hazardous operation.

Maximum gasoline losses or toxic emissions occur during underground storage tank filling and emptying operations.

Do you know where is petrol stored in petrol pumps?

At your local petrol station, huge quantities of petrol and other fuels are stored in an underground storage tank which is built underneath.

Fuel delivery staff at the petrol station regularly opens the storage tank lids to check the level during filling operations and during this time volatile components escape into the atmosphere.

Owing to the increased liquid level in the tank during filling operations, these fuel vapors are constantly released into the atmosphere causing air pollution.

2. Harmful Emissions during Normal Pumping Operations:

The underground storage tanks are provided with a vent pipe for air intake during pumping operations.

If the air intake is not there, a vacuum created inside the tank causes it to collapse.

During pumping out of petrol from the storage tanks there is a decrease in level.

As a result, air goes inside through the vent pipe into the storage tanks.

There is a vapor space over the liquid level which consists of volatile toxic components mixed with air.

The vent line must have a pressure/vacuum relief valve (PVRV) as a safety measure but in most of the fuel stations, it is not available.

Now you say, how does all this stuff cause a toxic release?

The pressure inside the storage tanks increases due to:-

- Changes in temperature (during peak summertime).

- Any additional air intake during pumping operations (due to the absence of PVRV)

Thus, when the pressure inside the storage tank increases, the vent pipe releases the volatile toxic components in the atmosphere.

PVRV protects the unwanted release of hydrocarbon vapors during normal conditions but in absence of the same minor toxic emissions occurs all the time.

3. Toxic Emissions during Tank Monitoring Operations

Fuel station operators open the top Cover of petrol storage tanks on a regular basis.

Why?

They check the fuel level and the presence of water inside the storage tanks.

When they open the cover, accumulated toxic vapors are released in an open atmosphere.

Sometimes, during level monitoring, operators insert a graduated dipstick inside the tank.

Some gasoline evaporates and is adsorbed on the wooden surface of the dipsticks.

Subsequently, these dipsticks are left in the open air.

The gasoline so adsorbed on the dipstick surface cause the evaporation of gasoline into the atmosphere

Though it is very minute in quantity, it acts as a contributor of hazardous emissions.

4. Hazardous Emissions during Vehicles Refuelling at Petrol Station

Refueling emissions occur during petrol filling when toxic vapors escape from the vehicle’s fuel tank.

During the refueling process, incoming liquid petrol constantly displaces the vapor space of the vehicle fuel tank.

The volume of displaced toxic vapors (VOC) is equivalent to:-

- The volume of the petrol dispensed into the vehicle fuel tank;

+

- The drops of liquid fuel vaporized due to dripping from the filling nozzle;

+

- Leakage from hoses and gaskets.

VOC released during the refueling operations depends on the following factors :

- The temperature of petrol inside the vehicle fuel tank

- The temperature of petrol dispensed

- RVP – Reid vapor pressure

- The volume of dispensed petrol

5. Evaporative Emissions from Parked Vehicles

On sunny days, the vehicles parked under the sun eventually heats up.

This causes evaporative emission from the fuel contained in the engine and the fuel system of a parked vehicle.

So how to control the toxic evaporative emissions?

Please ensure not to park your vehicles in the direct sunlight (use covered parking stations).

Adverse Effects of Toxic Fume Emissions [Fuel Contaminants]

| Petroleum products at fuel stations contain traces of benzene, toluene, and xylene (BTX) all of which are harmful toxic pollutants causing exposure-related health effects in human beings. |

Benzene which is present in petroleum products such as petrol and diesel is currently classified as a human carcinogen (Contains cancer-causing substances) by the US Environmental protection agency (EPA).

A study conducted by The Energy and Resources Institute (TERI) at 40 petrol pumps of Delhi (India) has found that the level of toxic fumes containing fuel contaminants (BTX) is several thousand times higher than the permissible limits.

In their findings, they highlighted the high concentration of volatile organic compounds including benzene at various petrol pumps, exposure, and the ill impacts on health.

Benzene has a tendency to vaporize rapidly and this component is present as vapor in the atmosphere in and around the petrol stations.

It quickly evaporates inside the vehicle’s fuel tank and fills the space above the liquid fuel.

During vehicle refueling, these vapors came out from the fuel tank as explained earlier.

One more study was done by the Indian Oil Corporation (IOCL) and Society of Automotive Engineers International jointly in which the published report provides an indication of ambient levels of benzene in the immediate vicinity of petrol stations in Delhi and NCR (National Capital Region).

A study by National Ambient Air Quality Standard of India says:-

The average concentrations of benzene ranged between 2.28 ppb to 9.43 ppb which was higher than the limiting value of 1.56 ppb.

Type of Health Effects

Benzene being a human carcinogen, the globally accepted standard in petrol is 1 percent by volume but still in some parts of India, petrol pumps are selling unleaded petrol having a benzene content of about 3 to 5 percent.

During peak hours, when there is a high concentration of vehicles at the petrol pumps, toxic exposures are very high.

Exposure to BTX (specifically Benzene) poses the following health hazards:

- Acute – Eye irritation/watering, Nose irritation, Throat irritation, Headache, Nausea/Vomiting, Dizziness, Asthma exacerbation

- Chronic –Cancer, Central Nervous System damage, Liver damage, Kidney damage

VOC emissions contribute to the formation of ground-level ozone causing smog, which increases mortality rates and respiratory-related hospitalizations. Ozone also damages materials, crops, and ecosystems.

How to Reduce Toxic Emissions at Petrol Stations

Installing a vapour recovery system can reduce toxic emissions at Petrol Stations.

Let’s see how?

What is a Vapour Recovery System at Fuel Station

Vapor recovery systems not only help to curb the release of toxic volatile organic compounds but also reduce evaporative losses of valuable fuel.

A vapor recovery device is an equipment/system to capture displaced vapors that emerge from inside of a vehicle’s fuel tank when petrol or diesel is dispensed into it.

Vapor recovery system are of two types –

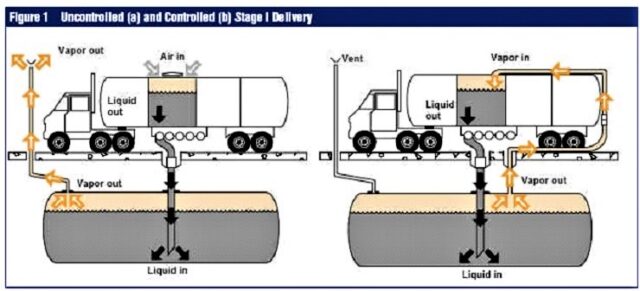

- Stage 1 Vapor Recovery (VR1) – It captures the toxic emissions from underground storage tanks when they are being filled by road tankers.

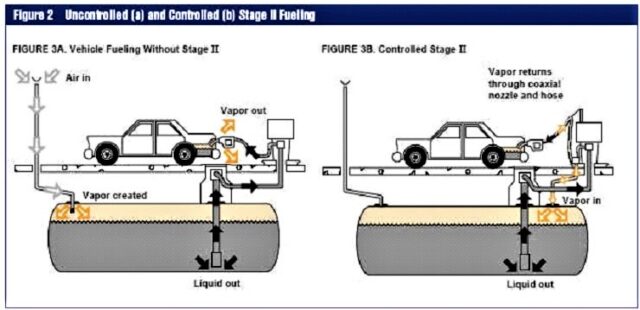

- Stage 2 Vapor Recovery (VR2) – It controls the emissions from filling vehicle tanks at the petrol pump.

How Vapour Recovery System Reduce Toxic Emissions

This system works in two stages as explained below-

Stage 1 Vapour Recovery System

VR1 involves the collection of the vapor occupying the empty space in the underground petrol storage tank while the tank is being filled by the road tanker.

The vapor displaced by the rising liquid level is fed into the vapor space of the tanker as the liquid level in the tanker falls.

Stage one vapour recovery system provides a closed-loop of liquid and vapor transfer between the tank and tanker. See the diagram below.

At the terminal, during refilling, the vapor displaced from the tanker is collected through the gantry and returned to the terminal storage tank via a vapor recovery unit that condenses the vapor into a liquid.

Condensers and/or activated carbon beds commonly control vapor release from the storage tanks at the terminal.

The equipment modifications required to consist of additional piping for the vapor transfer.

For VR1, this involves underground excavation to install pipe-work to the storage tank, and additional pipe-work and connections on the road tanker.

Stage 2 Vapour Recovery System

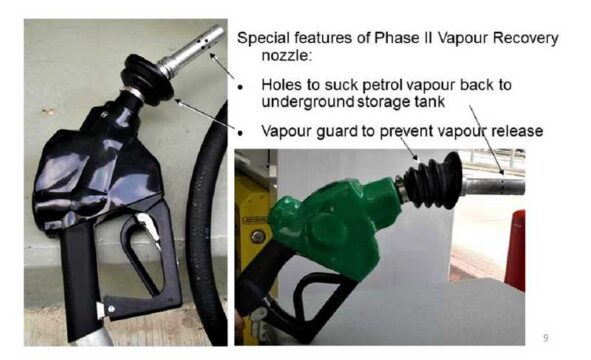

During refueling, VR2 captures petrol vapors at the petrol pump.

Stage 2 vapour recovery system captures the vapors in the vehicle’s fuel tank itself and then transfers these vapors into the underground storage tank, thus preventing their release into the atmosphere.

See the diagram below

During the installation of the VR2 recovery system, a vacuum pump (in addition to the vapor piping system) is required to create suction to return the vapor from the vehicle’s petrol tank to the underground tank.

It ensures that no vapor escapes from the space around the nozzle.

This vacuum is controlled to capture at least 95 percent of petrol vapors.

In the early nineties, VR2 technology was first introduced in Europe and the United States.

Numerous countries can install this technology where petrol vapor emissions are the prime cause of local and regional air pollution.

VR1 and VR2 technology = Best practice for the management of petroleum vapors

Vapour Recovery System in India

CPCB (Central Pollution control board) in their letter to Oil marketing companies (IOCL/HPCL/BPCL) said that:

All retail outlets with a capacity of 300 KL/Month (in 46 cities with a million-plus population) and more must install Stage I & II vapor recovery systems.

These vapour recovery systems shall have min 80% vapor recovery efficiency.

Also, all new retail outlets with a capacity of more than 300 KL/Month, which are getting commissioned after the date of issue of the above directive should come up with modern dispensing units with inbuilt VRS facilities.

Benefits of Installing Vapour Recovery System

Decrease in air pollution due to fewer VOC emissions released during petrol refueling processes.

VOCs are a precursor to ground-level ozone, which is harmful to human health, vegetation, and building materials.

VR2 system captures fugitive petrol vapors (fuel contaminants) that would otherwise be released as VOC emissions into the air.

Petrol vapors contain benzene, which is a human carcinogen.

Reducing petrol vapor at petrol service stations reduces people’s exposure to benzene.

Conclusion

Petroleum vapors contain a wide variety of volatile organic compounds (VOC).

These compounds are toxic and carcinogenic in nature (such as benzene) that affects people in and near the gas stations.

In India, controlling the aromatic content of gasoline and installation of a vapor recovery system during storage, loading, and unloading operations should be done on top priority.

After enforcement of Bharat IV norms (April 2017) and further movement towards Bharat VI, data shows that the percentage of benzene (in volume) has been reduced from 3 to 1 in petrol.

It is a healthy sign but every petrol pump outlet must follow this standard to eradicate the growing health hazard.

Strong regulations are required to reduce fuel vapor emissions in India and government agencies such as CPCB and NGT are working in the right direction.

Please let us know what you think about toxic emissions.

To join the Save Environment bandwagon consider subscribing bharatgogreen.

Please share this article to help others.